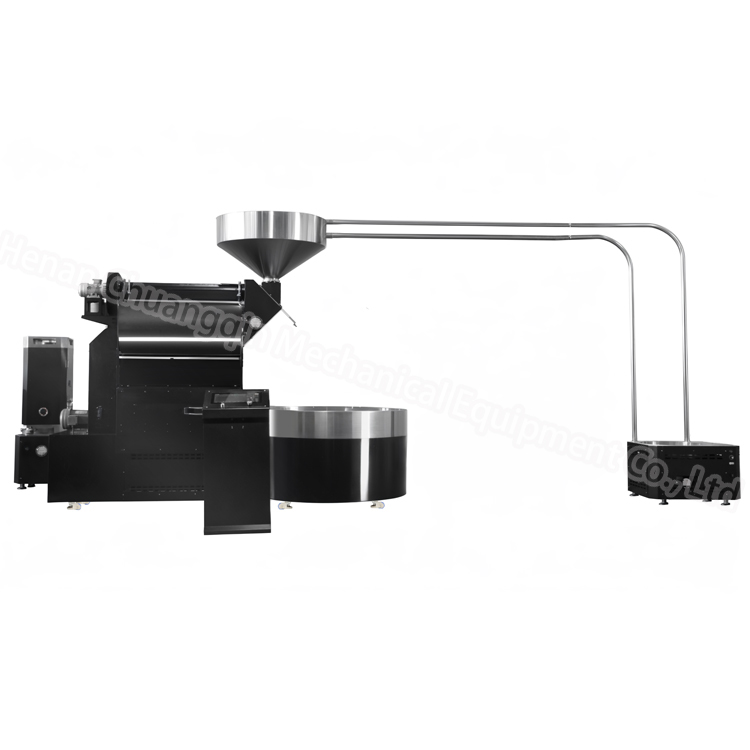

CQ-60kg coffe roaster mainly used for coffee factory or roasted beans business. It keeps attracting customers due to the large flexible roast capacity and its consistent repeatability.

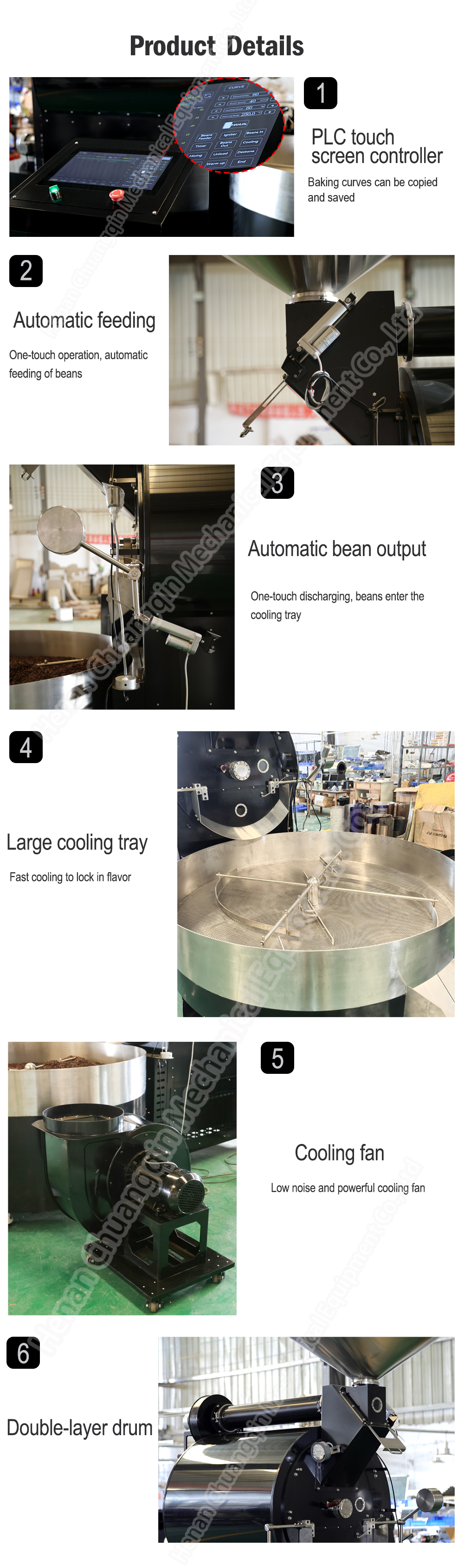

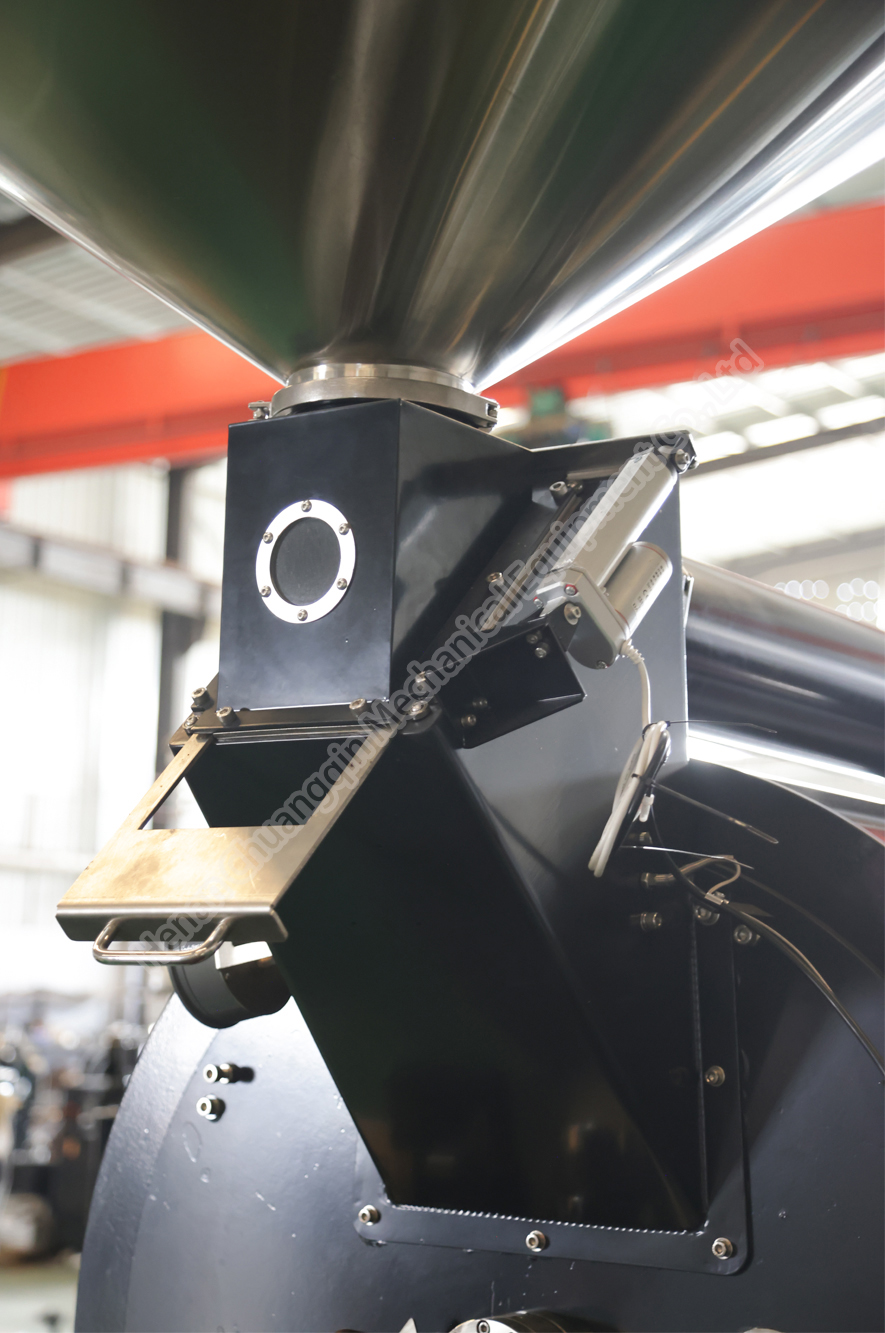

1. Fully computerized and automatic control of feeding, roasting, discharging, and cooling

2. Efficient thermal energy circulation management and utilization design, with significant energy-saving effects.

3. Adopting electric servo system, the machine operates sensitively, has a low failure rate, is stable and durable, and has a long service life.

4. PLC color touch screen microcomputer system, combined with human-machine interface, makes operation easier and can switch between multiple language interfaces.

5. PLC touch screen controller

6. Baking curves can be copied and saved

|

Model |

CQ-60kg |

|

Name |

60kg coffee roaster |

|

Heating source |

Natural Gas/Propane |

|

Bath capacity |

60kg(132lb) |

|

Average Roasting time |

15-25 minutes |

|

Production |

120-200 kg/h |

|

Voltage |

380V, 50/60Hz |

|

Roaster Power |

8.5KW |

|

Roaster Dimensions |

3200*2400*2800 mm |

|

Roaster Weight |

2000kg |

|

Drum Construction |

304 Stainless steel, double layers |

|

Body Color |

Black and white |

|

Data Logger |

Record roasting curve, USB or BT |

|

PLC system or control panel available for options |

|

1. Uniform bean appearance and homogeneous roast through the combined application of heat via convection and conduction.

2. Specific design of the roasting drum allows for a gentle mixing of the beans.

3. Reliable production from light to extremely dark roast colors.

4. Long roasting times with high production outputs.

5. Minimal product loss, minimal weight loss.

6. Effective and gentle cooling.

7. Reduced cycle times by simultaneous roasting and cooling.

8. Effective chaff separation by separate, free-standing roasting cyclone.